Warehouse of the future

Automating the order picking process

What does the warehouse of the future look like? It might include warehouses that extend vertically into the sky, rely on drones for delivery and utilize robots for lights-out order fulfillment. We all agree: The warehouse of the future is a fully automated warehouse in which divers processes are smart connected.

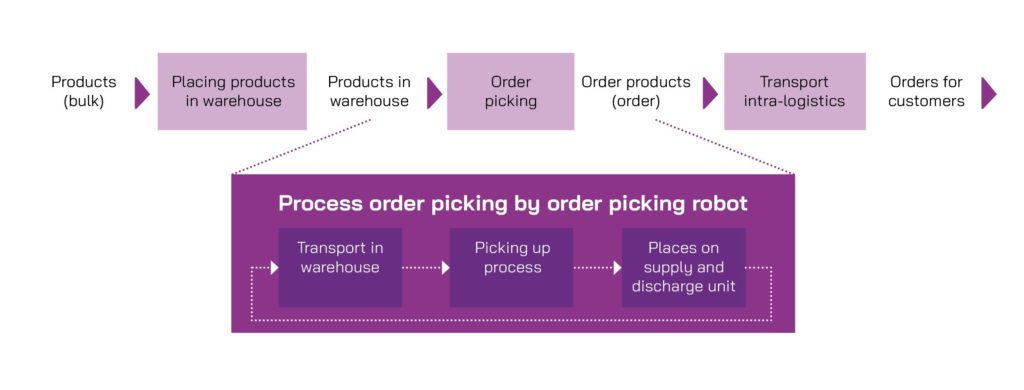

Figure 1 – process overview

Developing this Order Picking Robot

Developing this Order Picking Robot we had to divide the project into three modules.

- First of all, a new generation of robot control is developed in the robotics module, which recognizes small deviations and adjusts its actions accordingly.

- For the mobility of the Order Picking Robot, an AGV module is being developed. This AGV module focuses on autonomous movement and navigation in a warehouse, taking into account the dynamics and mechanics through the combination with the moving robot.

- The Supply/removal unit module focuses on processing the order; both physically and in terms of software: the products are organized on the Order Picking Robot in intra-logistical processes and also take care of the communication between the different systems.

Our contribution

This project is developed within a consortium of different parties (names) with all own responsibilities. With our Autonomous knowledge, Nobleo Technology developed module two which is responsible for the autonomous driving through a warehouse to follow the order picking process.

Three modules into one robot

These three modules are integrated to create the first proto-type Order Picking Robot. Figure 1 provides a schematic overview of the process in a warehouse and specification of the order pricking process.

The Order Picking Robot will fully automate the process of Order picking in a warehouse; when an order is placed, the order information is sent to the order picking Robot. The Robot then transports itself through the warehouse to the specific products from the order, picks it from a pallet or rack and places it on a supply/removal unit. The supply/removal unit serves to organize and register the complete order of products, after which they are supplied in the intra-logistics process.

The Order Picking Robot in six steps

1. The robot receives an order from Warehouse Management System (WMS)

2. Accurate positioning of the robot in front of the conveyor to pick up empty tote

3. Transporting empty tote to pick up location

4. Picking WMS orders at different locations and heights in the warehouse, putting products (different SKU’s) in tote

5. Transporting tote with products to the drop-off location

6. Mission complete. Repeat.