Predictive maintenance for bearing inspection

Nobleo developed algorithms for predictive maintenance of bearings.

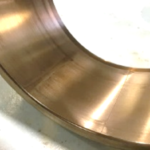

Figure 1 – Different SKF bearings

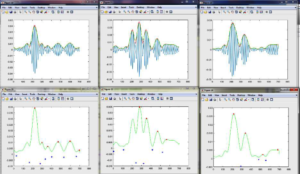

The main task was to perform impulse detection, its properties, its periodicity in the acceleration signal and separate the sources of different impulses. The main challenges were the noise level, sensor placement, different transfer functions, unknown machine condition (meta-data), insufficient labelled data.

Figure 2 – Impulse response of the bearing system

Several approaches have been tested: STFT+, wavelet packets + Shannon entropy, random forest, support vector machine, Bayesian inference with a hidden Markov Layer.

The algorithms developed within this project were transferred to the customer. The customer integrated the algorithm into an embedded sensor solution. Nobleo was actively involved in a follow-up project to industrialize the embedded sensor solution.

Please reach out to us if you are looking for:

- preventive maintenance algorithms

- sensor solution and signal processing know-how

- a partner to develop an embedded sensor solution (using custom hardware)