Packaging Line Feeder

Out the box thinking for box production system, turning batches into continuous flow

Out the box thinking for box production system

Turning batches into continuous flow

One of Europe’s largest beer brewers invited seven engineering consultancies to pitch for a robot system. The brewer wanted a robotic packaging line feeder to place folded boxes into a box erection system. Nobleo Technology was chosen, not because it suggested the smartest, most cost-effective, most reliable robot, we won the pitch because we proposed turning a stack of flat boxes into a continuous flow of flat boxes.

Previously, the flat boxes were loaded by the machine operator into the box erector system. The speed at which the box erection system worked effectively demanded that the operator spend 75% of his time manually loading flat boxes. Leaving only 25% of his time to attend to the more critical activity of operating and monitoring the packaging process.

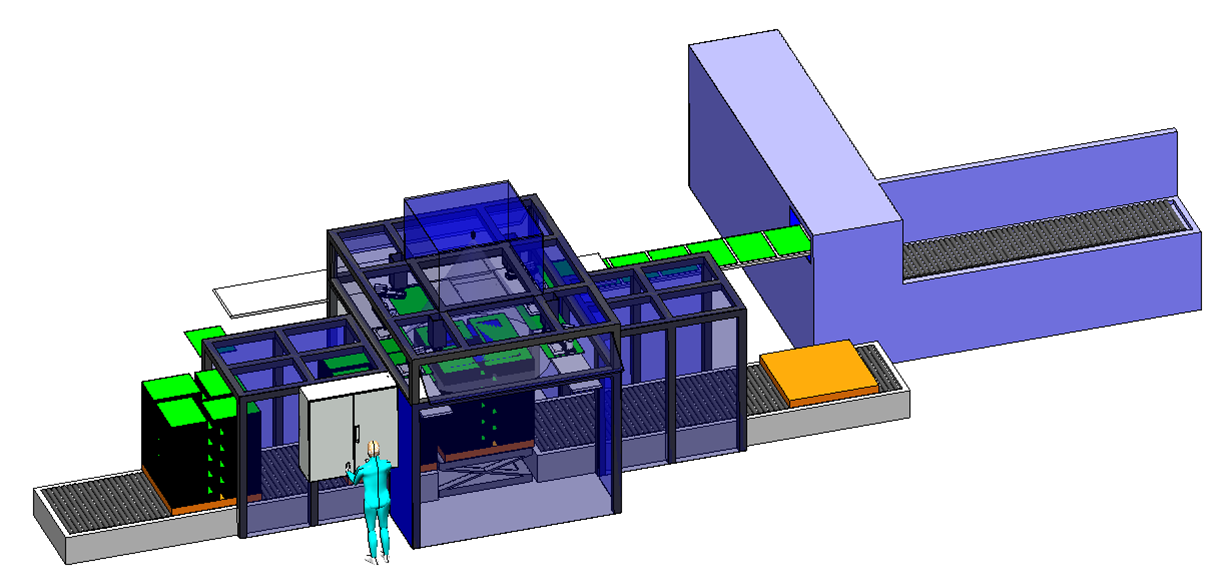

Text continues below picture

Six of the invited automation suppliers recommended robotic solutions

Six of the invited automation suppliers recommended robotic solutions that mimicked the human operator’s actions. Robots that grasped batches of flat boxes, moved them to the box erector, and placed them into the feeder shoot. But all of these solutions were complex and the high chances of error would be very time-consuming and expensive to correct.

We applied some “out the box” thinking and recommended an overhead conveyor system. This not only provided a simple, reliable delivery but also interfaced directly with the box erector. This effectively changed a batch delivery concept into a continuous flow. In addition, the factory gained shop floor flexibility since the palletized flat boxes could now be placed away from the packaging system and simply transported individually by the overhead conveyor system to the all the different packaging machines.

The new packaging system was successfully delivered in April 2017, and is now used in a number of breweries, after which worldwide roll out is scheduled. Initial results indeed confirm that the system is more robust, works with fewer disruptions, and provides higher OEE. Also fewer staff are required.

Nobleo Technology Packaging Line Feeder

- Simple to use

- Highly reliable

- High OEE

- Converting batch process to continuous flow