No man entry tank cleaning

Why risk human life, when a robot can do the job?

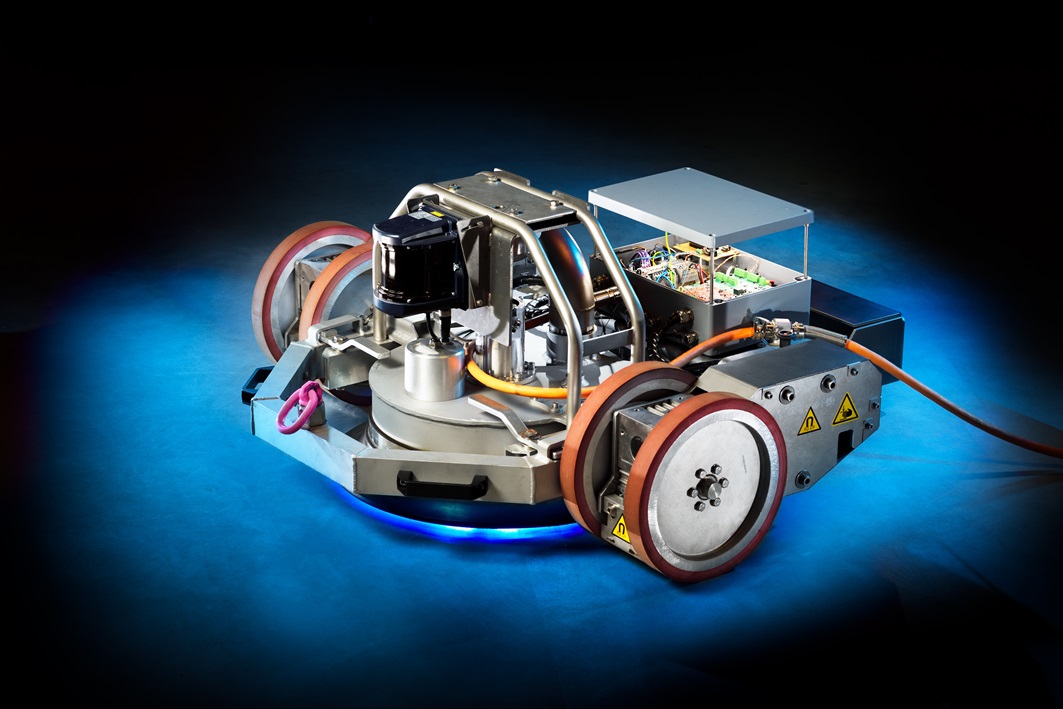

Fully autonomous cleaning system for petrochemical tanks

Why risk human life, when a robot can do the job?

Cleaning can be a dirty job. And each year, thousands of enormous steel tanks must be cleaned from the inside. These tanks are used to store petrochemical substances that are very unhealthy to humans. Even so, people still need to get inside these tanks and remotely control special cleaning systems, to clean the floors, walls and ceilings of these tanks. It´s a dirty and dangerous job, but someone´s got to do it.

At Nobleo Technology we believe that the “someone” should be a robot. Robots don’t need to breathe, so poisonous fumes are no problem. Also, if anything goes wrong, a robot can always be repaired.

That’s why we’ve made a fully autonomous cleaning system for these petrochemical tanks. Our system always knows where it is and it is capable of planning its own cleaning route. We’ve developed special software path models specifically for cleaning, as well as providing intelligence for the cleaning system to make decisions to overcome unforeseen circumstances.

It’s not surprising then that government authorities across the globe are seeking to abolish the presence of humans in petrochemical tanks by as early as 2020. This idea is a powerful example of how we are helping to make the world a safer and healthier place.

Nobleo Technology Unmanned Cleaning System

- Eliminating all cleaning risk to human life

- Cleaning done by fully autonomous systems

- Powerful example of making the world a safer and healthier place

Smart Tooling project within Interreg

Smart Tooling is a project within the European Subsidy program Interreg Vlaanderen-Nederland. In the Smart Tooling-project, with support of Interreg V Vlaanderen-Nederland, companies and service providers from the border area of the Netherlands and Belgium being brought together as partners to develop robot technology. The aim is to maken this more cost efficient, safer and stengthen the process industry.

KicMPi is responsible for the financial and content projhectmanagement of the Smart Tooling project in general. in this project the follwing partners are participating very closely together: BASF, Dow Benelux, Impuls Zeeland, REWIN, BOM, BEMAS, Sirris, Universiteit Gent, Universiteit Twente and Avans Hogeschool.