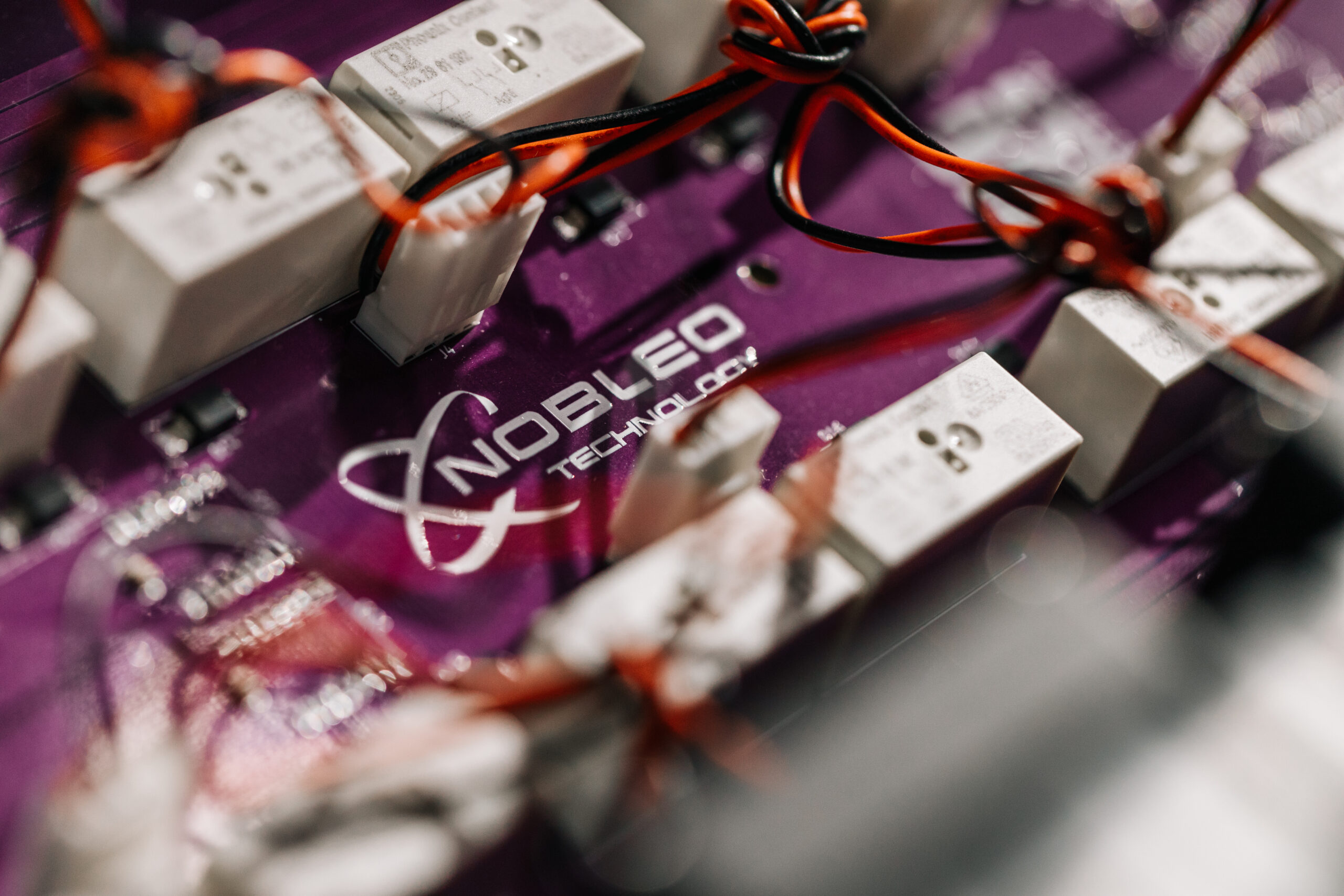

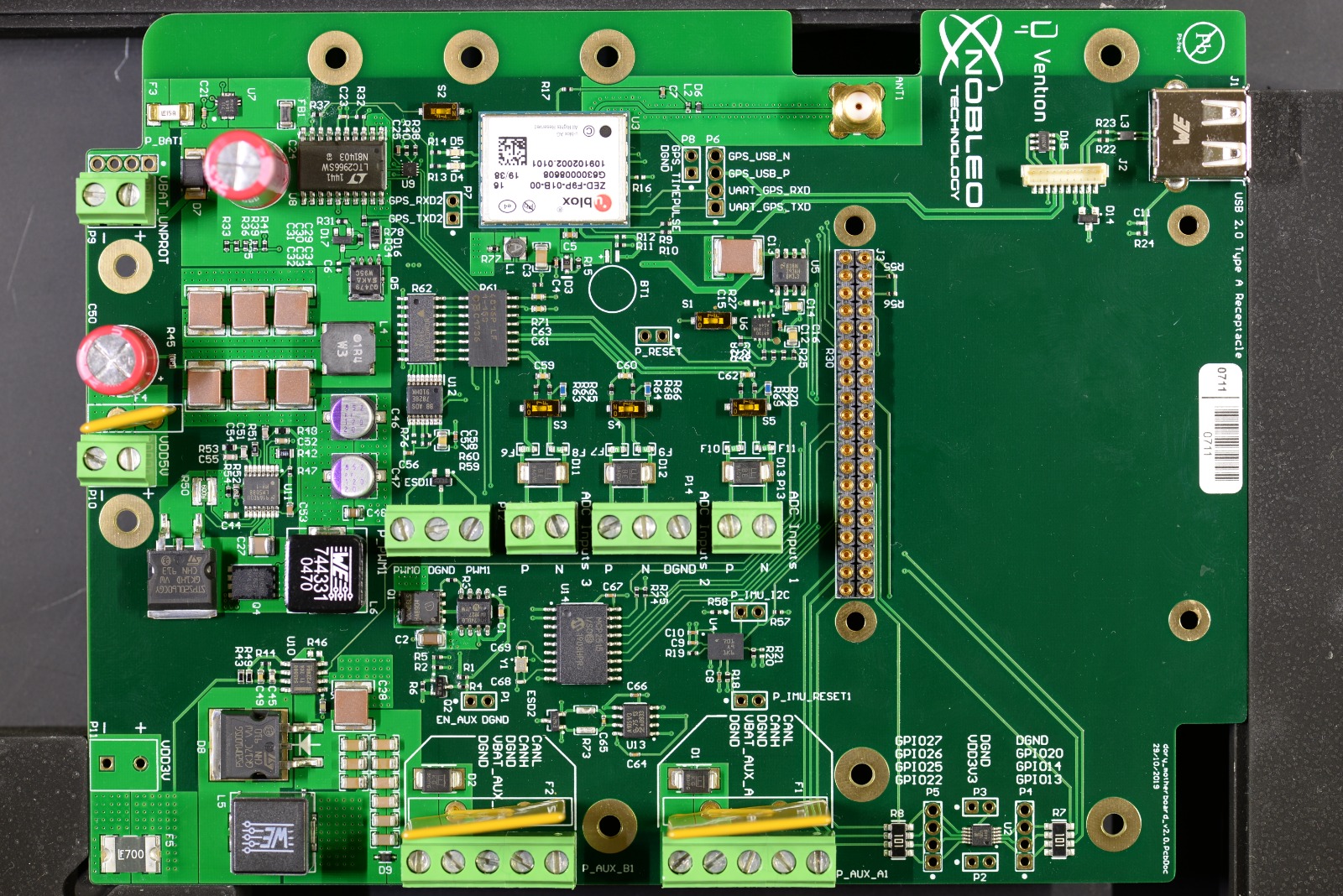

A modular control platform designed as a flexible foundation for product development across various domains.

The platform provides essential embedded control features and is intended to accelerate the development process by avoiding repetitive design tasks.

It offers integrated secure remote accessibility, supports over-the-air (OTA) updates, and is compliant with common connectivity standards, including Ethernet, Bluetooth, BLE, and Wi-Fi.

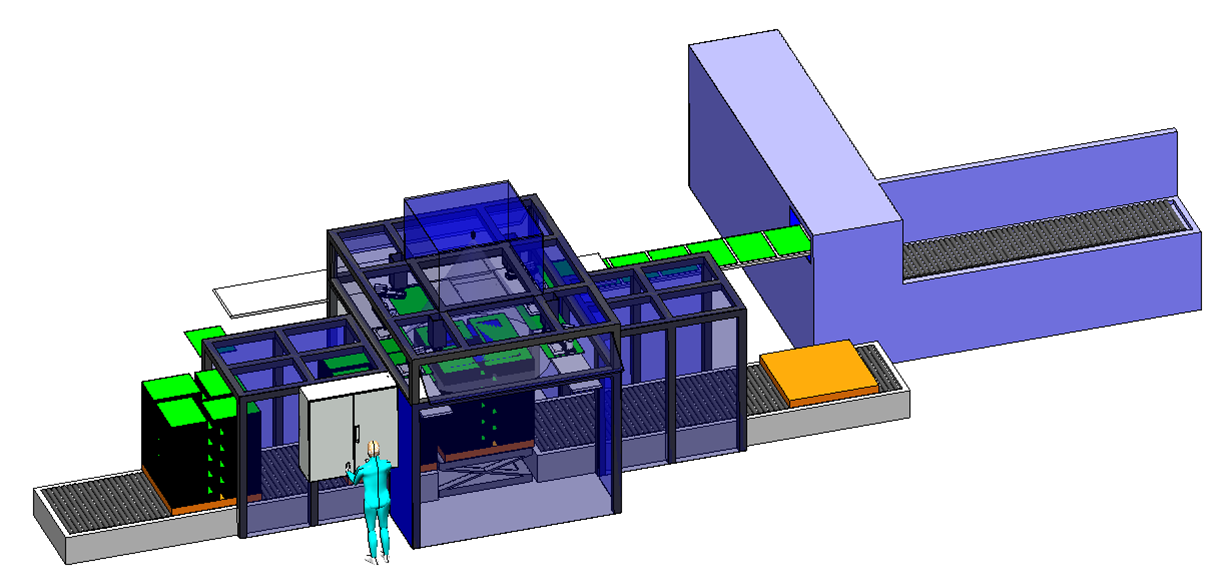

The modular architecture enables product-specific customization through predefined building blocks or customer-specific functional modules.

Security mechanisms are embedded at both firmware and system level, supporting secure data transmission and platform integrity throughout the device lifecycle.

The CoreBlox platform can be expanded with cloud connectivity options, advanced diagnostics features, and digital and analog input/output modules, providing flexibility for different application requirements.