Nobleo’s BSPs help Lely make farmers’ lives easier

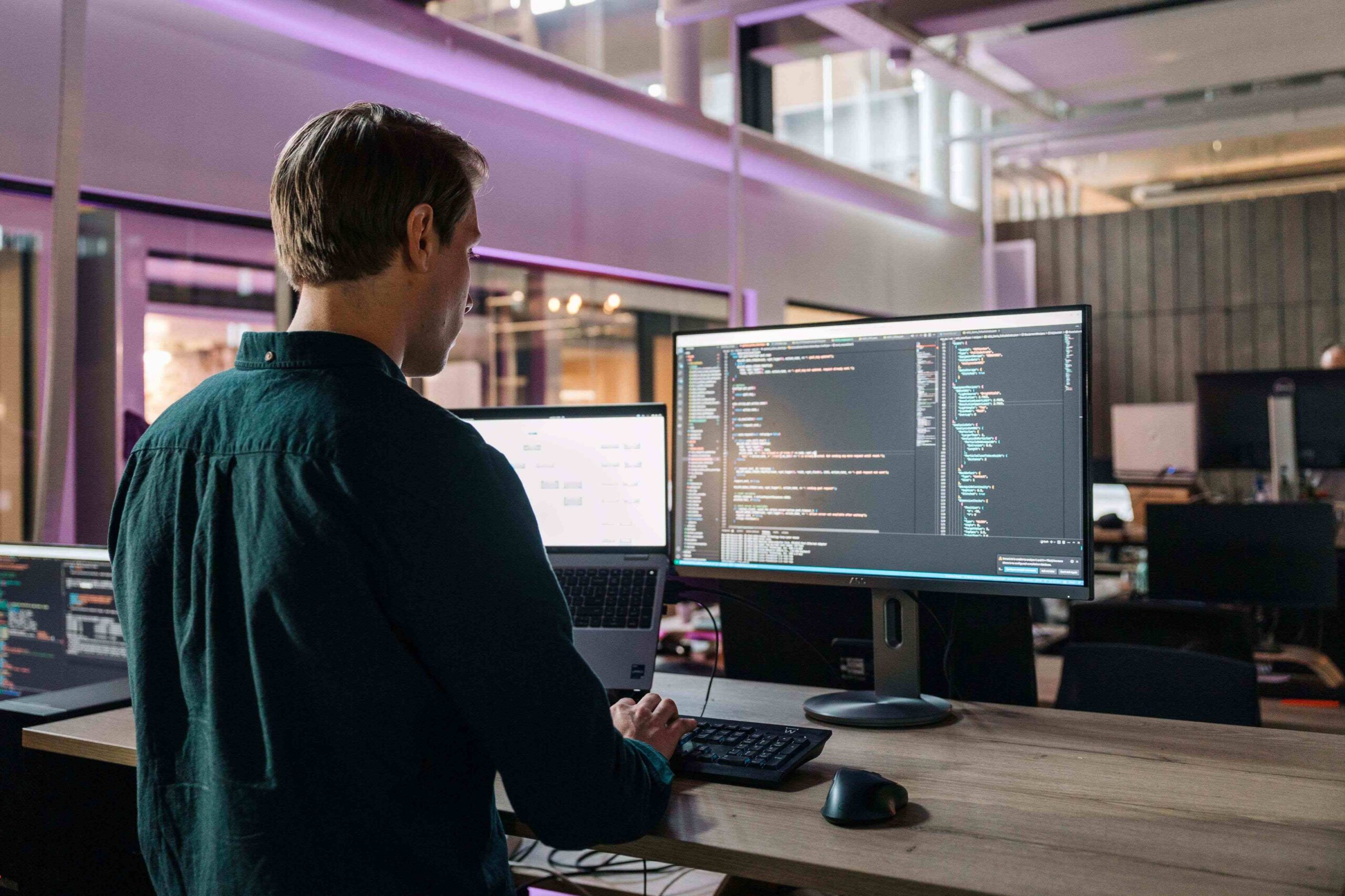

Nobleo carried out the first project for Lely towards end of 2017, debugging a Linux platform because of performance issues in the Vector robot system. “The successful delivery of a solution led to subsequent activities,” says Jorik de Vries, embedded software engineer at Nobleo Technology. “One that stood out was the development of the pro version of the robot controller, which is an X64 in-board CPU.”

Specialized in BSPs

Since the start of that project, Nobleo has carried out multiple projects related to Board Support Packages (BSP) for Lely. “We’re specialised in BSPs,” adds Tim Gruijters, also an embedded software engineer at Nobleo. “In general a BSP has three most important components; A bootloader which contains the startup sequence of the device, a set of drivers to make sure that hardware works well and the Root File System where all essential system files and services are.”

One of the inherent challenges with BSPs is that the hardware setup is always different. Including or excluding a Wi-Fi chip, for example, writing data towards memory and do proper memory management, or in terms of architecture. When something goes wrong, it can be very difficult to find the root cause.

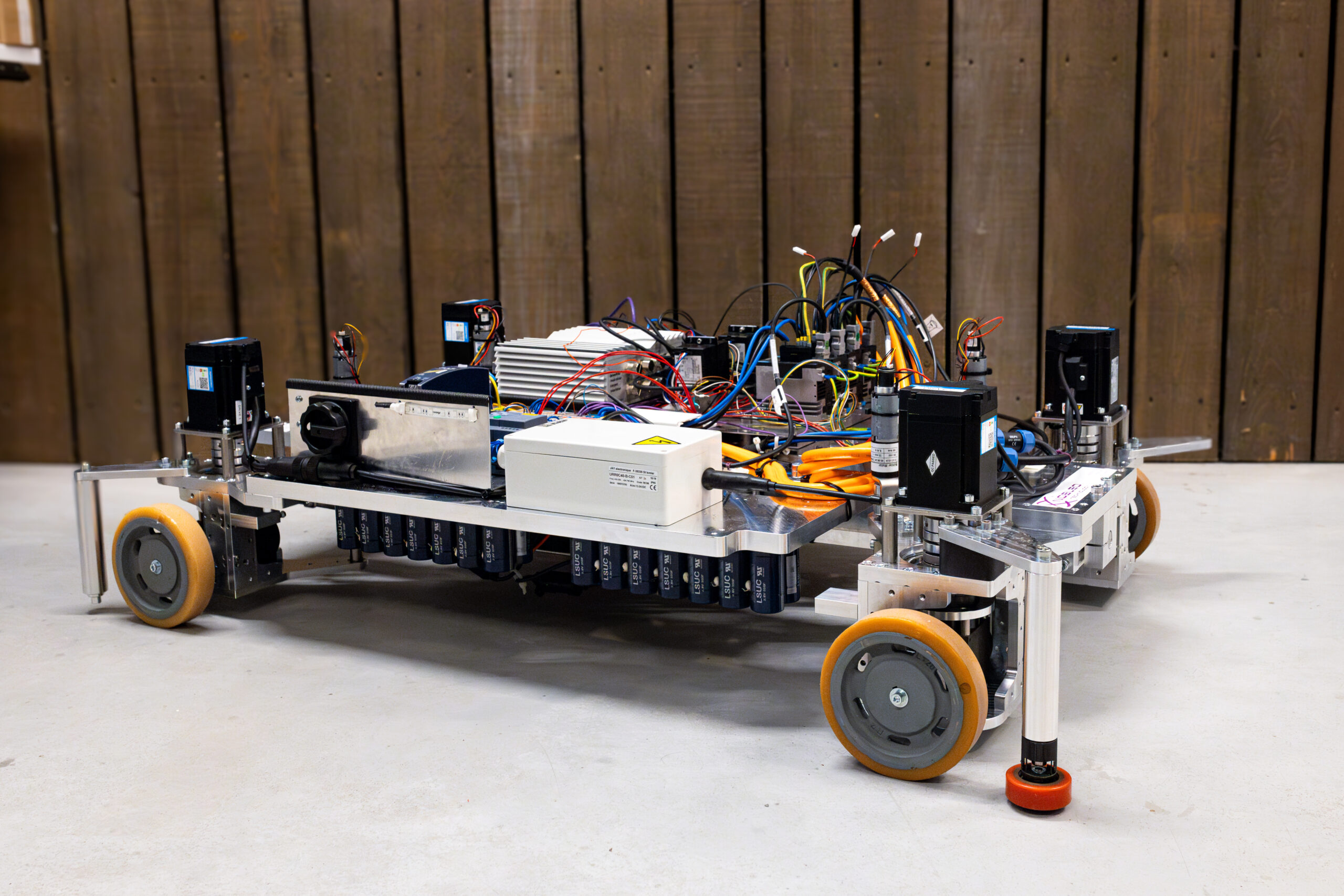

Customised control systems

“We essentially create customised control systems for Lely’s hardware,” says Bas Caljouw, business developer at Nobleo. “When they deliver a robotic milking system to a client, there are maybe 20 or 30 different boards in there, each with a CPU and/or MCU on board. Some controller devices may be connected to a screen, or a keyboard, or have different inputs than the others… It’s critical that all these boards can communicate with the robot system as seamlessly as possible. Also in such a way, when a technician has to fix an issue, there is a high degree of standardisation.”

A relatively unique specialism

To be able to do this, you need a lot of specialist knowledge in many areas – e.g. kernels, drivers, configurations – to figure out what’s going on. “It has to do with experience, and knowledge of both hardware and software,” says Tim. “Not a lot people have enough experience in this area. We’ve done a lot of these projects, so we know what questions we have to ask hardware suppliers, as well as customers like Lely. It’s our core business.”

Getting involved early

“Our preference is to be involved as early as possible in the hardware specification process, because we can give essential advice, based on our software expertise,” says Jorik. “This can make the solution simpler and more effective or even help to optimize the production process”. Choices of electronic components you are going to use are essential for each control system. To give another example, we have written installation procedures for hardware manufacturers so that our BSPs can be installed optimally.”

Chain of trust

Nobleo has recently become involved in the security of Lely systems as well. “You obviously have to make sure that your system is not hackable, and everyone works with secure passwords and such,” says Tim. “But there’s more to it than that. It’s also about the ‘chain of trust’. When you start up the CPU, every step before you get to the kernel has to be verified. We’re working on this, together with Lely and other companies like manufacturers of electronics who issue verification certificates. So it’s really a collaborative relationship.”

The relationship between Lely and Nobleo is ongoing. “Essentially we’re seen as a partner who makes sure the operating system runs in a correct way and is suitable for various board families used by Lely, while making sure they continue to function as required,” says Bas. “We’re called upon if anything non-standard is required.”

Persistent – or even irritating!

In terms of the overall value provided by Nobleo, Jorik carefully chooses his words. “I’m not sure how to phrase this correctly, but I think we are as persistent – or even a bit irritating sometimes – as we have to make sure the project is completed successfully,” he says. “We’re independent, so we’re not scared of asking difficult questions,” adds Bas. “That’s not always fun, or easy, but it does lead to higher quality solutions. Plus, we’re not obliged to recommend any specific hardware. We can take an objective look at what works best, rather than be tied to our own products or to a particular vendor.”

About Lely

Lely is an international family business specialised in innovative, automated solutions for the agricultural sector. It operates in three main categories: milking, feeding and housing & caring. Lely’s advanced robotic milking solutions are designed so “the cows decide themselves when to eat, drink, relax or be milked.”