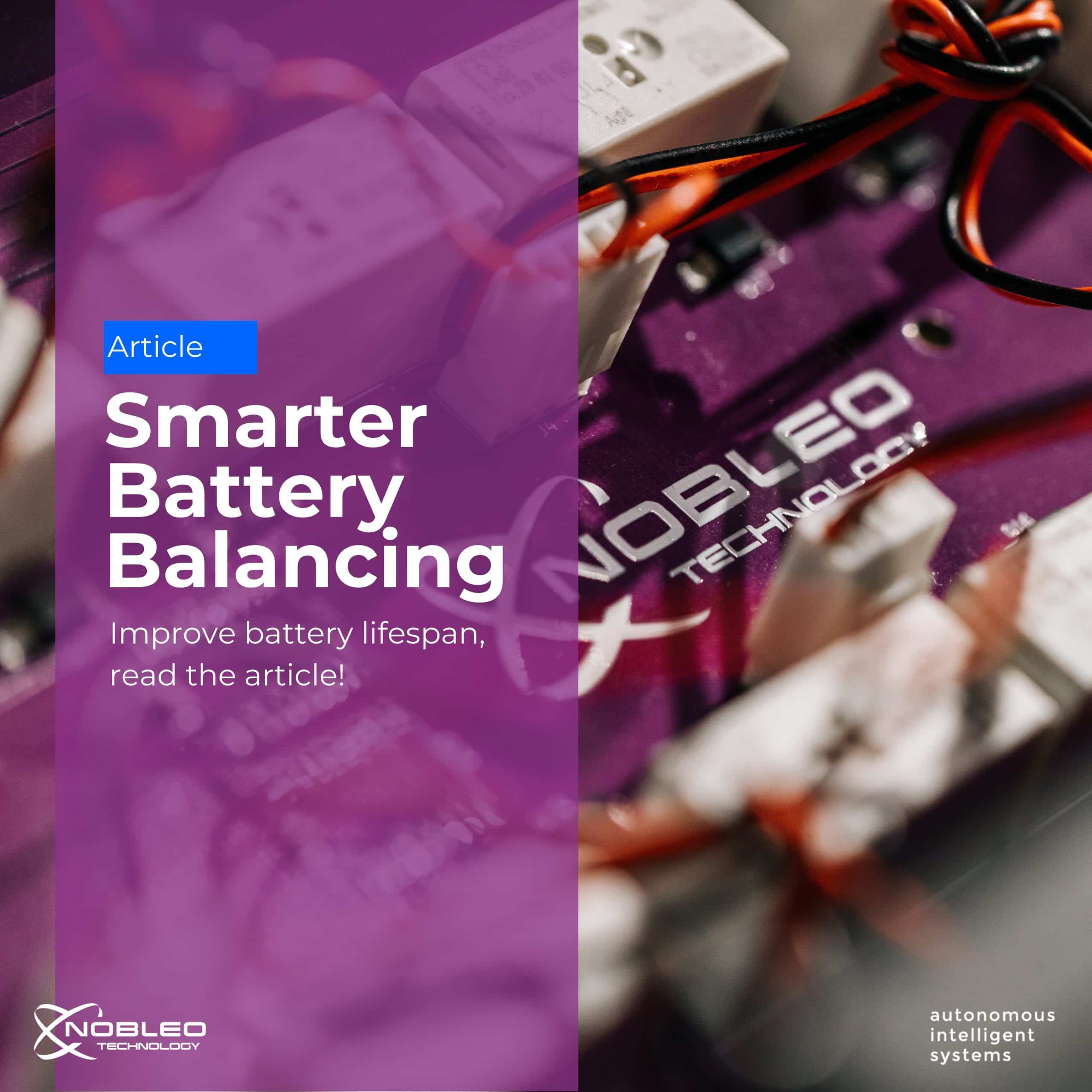

Battery balancing improves efficiency while reducing environmental impact

Interested in how battery balancing can help your company work more efficiently and sustainably? Read our latest article!

Battery balancing improves efficiency while reducing environmental impact

“Battery packs are, to put it simply, a number of battery cells connected together in series,” says Nobleo system architect Davy Bijnen. “Typically there is a variation in the properties of each battery, due to production inaccuracies and the conditions under which the cells operate. For example, cells in the middle usually heat up more than the ones at the end. And temperature has a big influence on how a battery cell performs.”

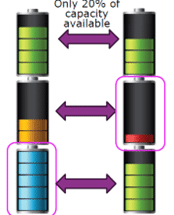

This diagram illustrates what can happen to unbalanced cells in a battery pack. If one cell is weaker (i.e. has less capacity) than the others, it will empty faster. Once it is empty, the whole battery pack needs recharging. But the other cells are not empty, and once they become full again, charging stops. This means the weak cell never recharges fully, and the overall capacity of the battery pack is diminished. Plus, charging has to take place more often than when the pack is in optimum condition. This gets worse over time, and diminishes the effective capacity of the pack.

Various methods of battery balancing

“There are many different types of balancing possible,” says Bas de Wit, electrical architect at Nobleo. “The simplest is passive balancing. You connect a resistor to each cell. Once you activate that connection, you can drain full cells individually (the stored charge dissipates as heat in the resistor), until they reach approximately the same level as a weaker (almost empty) cell. After that you can then bring them all up to the maximum level again.”

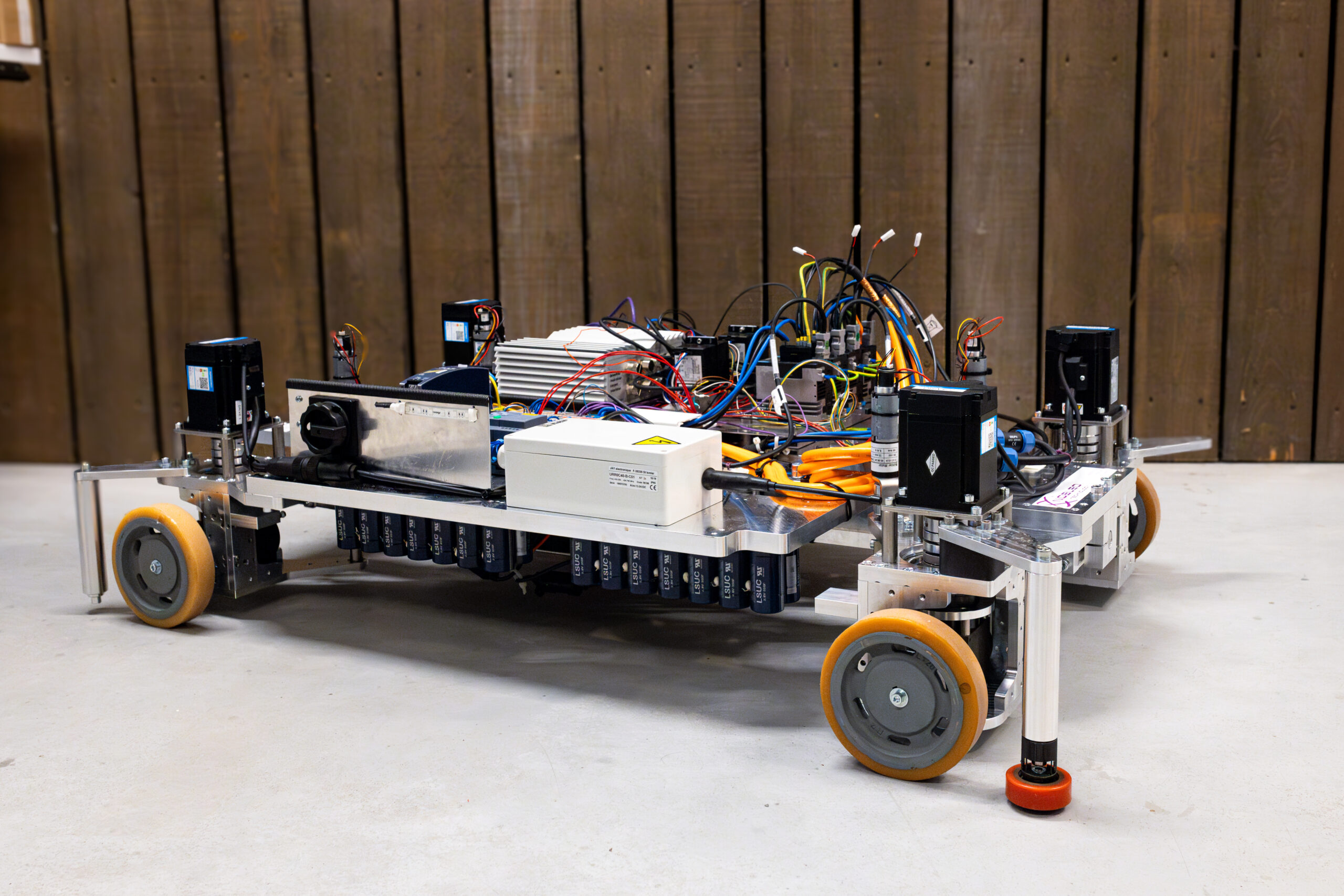

“What you typically see is that the BMS (battery management systems) of battery packs have resistors for this purpose, but they are small,” adds Davy. “For one of our customers, we saw this was insufficient and incompatible with the already-installed production line, and so created a separate solution, to include in the production line, with much greater power. The solution was therefore on a considerably larger scale than normal.”

Qualifying and conditioning

Nobleo offers various other options in addition to passive balancing. One example is qualifying and conditioning battery packs during production, in use or after use. This involves carefully measuring the battery cells to determine their condition, and then ‘upgrading’ them so they once again perform efficiently.

“We typically mix a systematic model-based approach with early vertical integration for maximum effectiveness,” says Davy. “It’s always a tailor-made solution, because no two battery systems are the same. There are all kinds of dynamic effects that play a role in how a battery pack behaves. The type of cells used, the load case, environmental factors, temperature…”

Consultancy

Another typical scenario is that a system integrator, who assembles equipment which includes battery packs, doesn’t necessarily have the knowledge to configure a battery management system in a way that tackles balancing issues or manages an array of battery cells in the most efficient way. “In situations like that we offer consultancy, so that it becomes possible for companies like that to get more out of the battery packs they use,” says Bas Caljouw, business developer at Nobleo.

Environmental advantages

“We’re currently working on turning our expertise in balancing into a commercial product,” he continues. “The balancing system we developed currently has a technology readiness level (TRL) of 7, which is only one step away from being complete and qualified. We’re very excited about this, because balancing leads to improved battery performance and life expectancy, which obviously increases efficiency. And it’s also good for the environment – the longer you can use batteries, the less waste you will have.”

Real-time active balancing

Nobleo is partnering Inmotion from the Eindhoven University Of Technology to explore the possibilities of real-time battery balancing in an electric race car that will take part in the 24 Hours of Le Mans. “Obviously every component in a race car has to be optimised,” says Bas de Wit. “If you can squeeze even 2-3% more out of a battery, it could make the difference between winning and losing. We’re currently looking at how active balancing could improve the car’s performance. We also aim to integrate this balancing function in a generic, multi-purpose BMS platform we’re developing.”