Getting grip on your development process

3 min read

3 min read - 13 Nov 2020

Standardized Way of Working, the road to success

Getting grip on your development process: Our Way Of Working

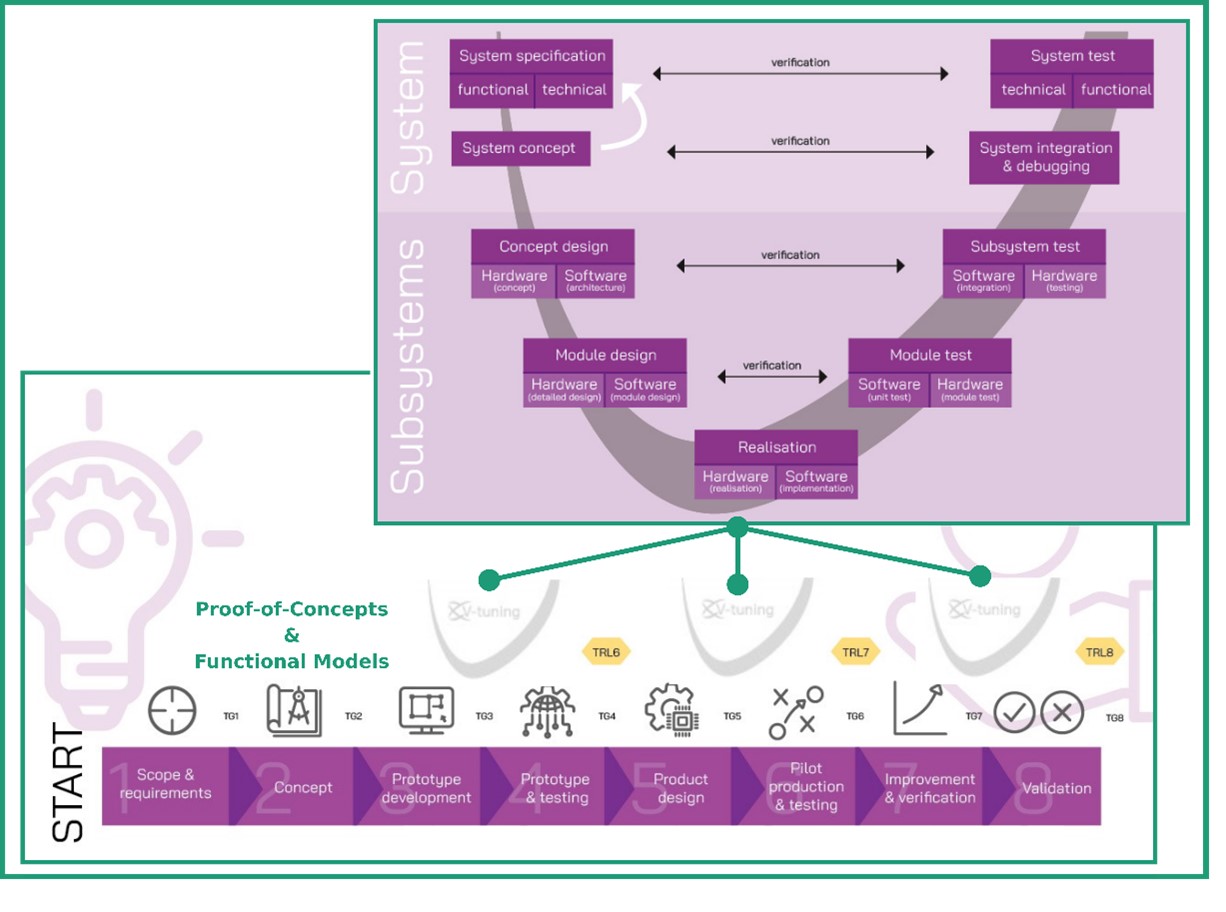

At Nobleo Technology we execute our projects according to both V-model and Agile model. It is important to decide at the start of the project which type of approach is best fit for the project. Based on the Cynefin framework you could say that projects that are well specified, well understood and well scoped, where best- and good-practice can be applied, are the best fit for the V-model. For more complex projects with more uncertainties, less constraints and more variables it is better to use an Agile approach.

Our stage gated approach in combination with the use of the well know V-model gives us a good structure to tackle our problems and this results in a high level of quality of the development. Furthermore, with this way of working our customers can keep clear track of the progress and obtain valuable deliverables.

One of the big plusses of the V-model is in its core of closing the loop from design to verification and validation. At Nobleo Technology there is no doubt that most value is generated when used early on, even already during the concept development. It is in this phase that identified design risks can be tackled early on, saving time and cost on the long-run. Because of this, at Nobleo Technology, we prefer and are well-equipped to build Proof-of-Concept setups and Functional Models (FuMos) in a ‘fast-lane’ manner. Coupling the use of Proof-of-Concept setups or Fumo’s with the V-model provides valuable feedback on design choices early on and help a lot in making key decisions for the technical design. This is of course a big benefit for the customers’ project.

After the concept phase, we can help with the same tools as in the proto-type development and test phase bringing your project to Technology Readiness Level 6 (TRL6) and we can assist to bring the project further to the pilot phase (TRL7) and to a final, complete and qualified product (TRL8).

Our stage gated approach with the use of the V-model

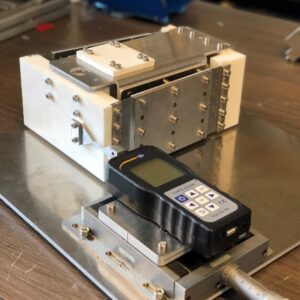

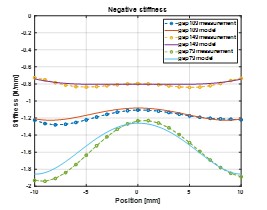

To obtain required improvements in the force budget in a very accurately actuated mechanism, we proposed to use a negative stiffness implementation by the use of magnets. Despite initial doubts at project partners, a Proof-of-concept setup showcased good predictive results, which are sufficiently robust for the applicable tolerances. With this result the force budget was improved and confidence was gained in the design.

Proof-of-concept-setup

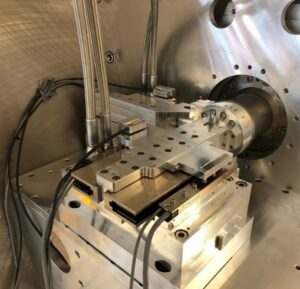

FUMO

To determine the best actuator solution (direct drive or in-direct drive) for a high tech system, two FuMos were built. The testing with these FuMos provided the necessary data to verify that the in–direct drive has clear and non-intuitive advantages for this case, making it a clear winner. This comparison on direct vs in-direct drive was published in Mikroniek(2020-04) and more can be read here.

Indirect drive FUMO Direct drive FUMOÂ

So, do you have a mechatronic challenging project and want to benefit from our V-models design approach of and fast way of developing and building Proof-of-Concept setups/FuMos to verify design choices? And do you need help to bring your project up until the TRL8 level? Please contact us.