Warehouse of the future – fully automated order picking robot

Nobleo’s smart AMR control software for logistics success

Autonomous warehouse picking technology: Automating the order picking process

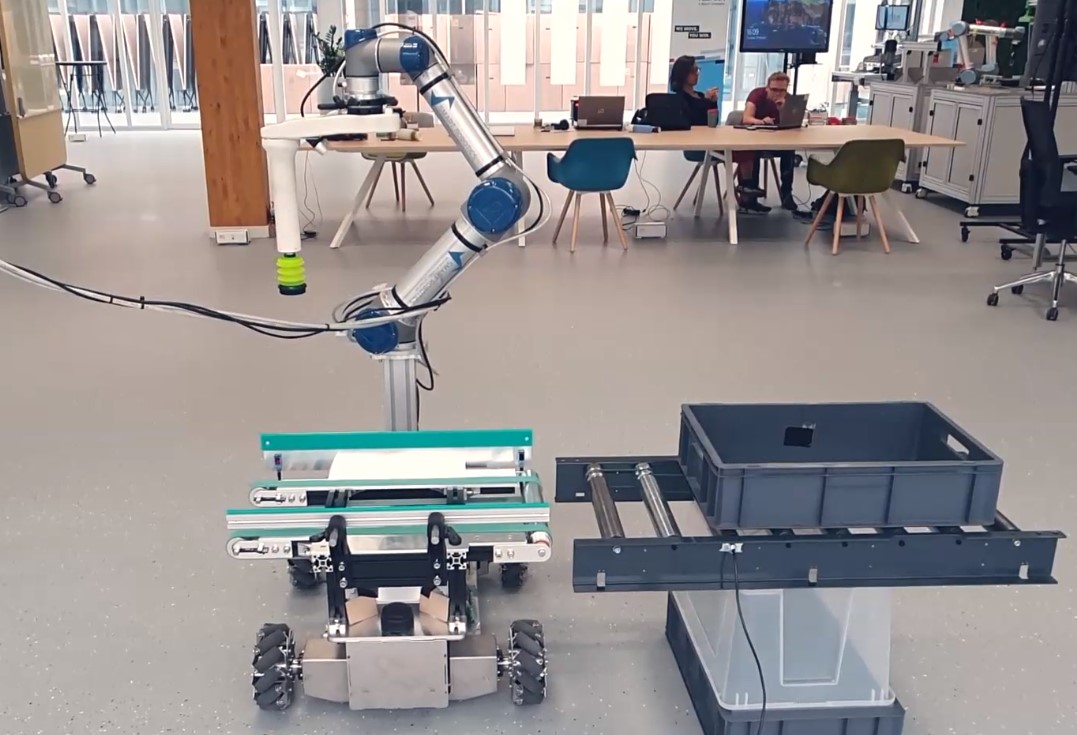

The warehouse of the future relies on autonomous warehouse picking technology. Nobleo develops the control and navigation software that enables robots to move independently, make smart decisions and adapt to changing conditions. As a result, these robots can take over repetitive order picking tasks. Together with industry partners, we created a modular system architecture that integrates robot control, autonomous mobility and logistical coordination.

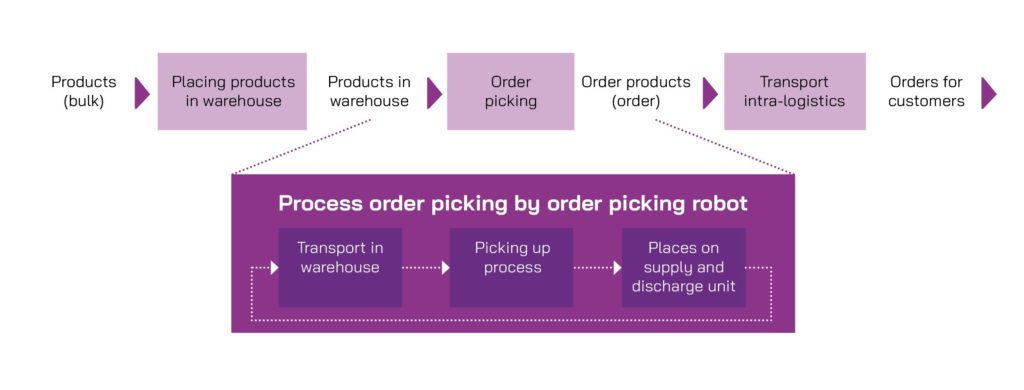

Figure 1 – process overview

Developing autonomous warehouse picking technology

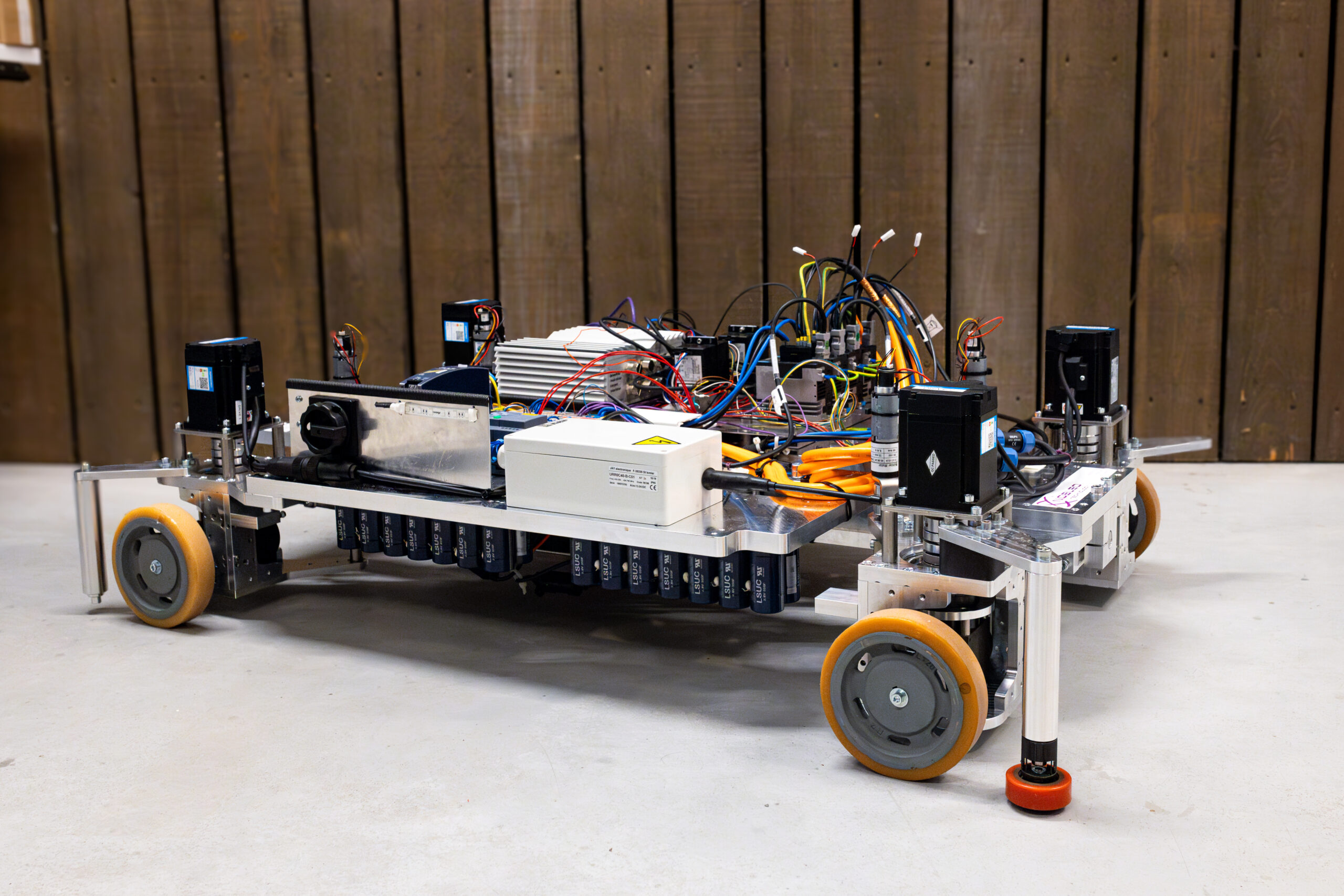

This project was developed in collaboration with industry partners, each responsible for a specific module. Based on our autonomous robotic expertise, Nobleo Technology developed the AGV module — the brain behind the robot’s ability to move autonomously through the warehouse and follow the order picking process without human intervention.

To realise this autonomous warehouse picking technology, the system was divided into three functional modules:

-

robot control module

This module focuses on accurate motion control. It detects small deviations during operation and adjusts movements in real time, ensuring smooth and reliable product handling. -

AGV (autonomous guided vehicle) module

Developed by Nobleo Technology, this module enables the robot to navigate the warehouse independently. It combines navigation algorithms with real-time environment sensing to adapt to obstacles, layouts and dynamic surroundings. -

supply/removal unit module

This unit manages the physical and digital handling of orders. It organises products on the robot and ensures seamless data exchange between systems within the intralogistics process.

First prototype of an autonomous order picking robot

The three modules were successfully integrated into a working prototype of an autonomous order picking robot. Figure 1 provides a schematic overview of the intralogistics flow and illustrates how the modules interact during the order picking process.

Once an order is received, the robot automatically retrieves the order data from the warehouse management system. It then navigates through the warehouse to the correct locations, picks the required items from pallets or racks and places them in a tote on the supply/removal unit.

The supply/removal unit organises the collected products and registers the completed order. From there, the products continue through the intralogistics process for further handling or shipment.

The order picking robot in six steps

1. The robot receives an order from Warehouse Management System (WMS)

2. Accurate positioning of the robot in front of the conveyor to pick up empty tote

3. Transporting empty tote to pick up location

4. Navigates to pick locations, placing various SKUs into the tote

5. Transporting tote with products to the drop-off location

6. Mission complete. Repeat.