Agxeed Agbot autonomous tractor software developed by Nobleo

Discover how Nobleo developed the autonomy software for the AgXeed AgBot, a fully autonomous robot tractor for independent fieldwork.

Discover the software behind the Agxeed Agbot autonomous tractor

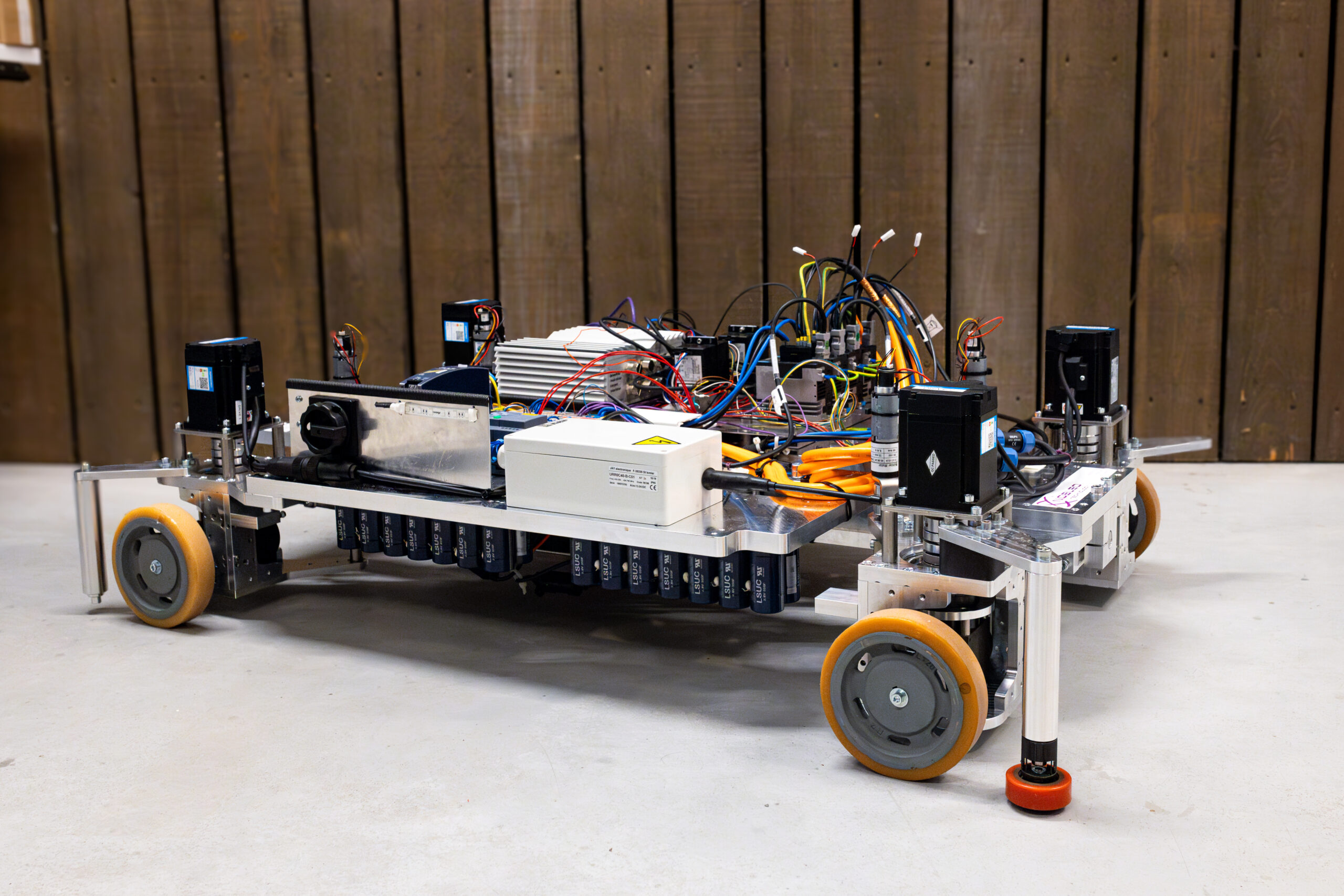

The AgBot, developed by AgXeed, is not just a tractor without a cabin – it’s a fully autonomous field machine. Nobleo Technology was responsible for the autonomy software that enables the AgBot to execute complete field plans without any manual intervention.

In this video (spoken in Dutch, with English transcript below), Ferry Schoenmakers – autonomy expert at Nobleo – explains how this robot tractor works, what makes it unique, and how Nobleo’s autonomy stack controls operations like ploughing, sowing and tilling.

From GPS and LiDAR integration to implement control and safety systems: discover the engineering behind the machine.

Watch the video below.

Transcript:

Ferry Schoenmakers (Nobleo Technology):

We are hired by the company AgXeed. AgXeed builds this autonomous tractor, and we at Nobleo are responsible for the software on this autonomous tractor.

Interviewer:

What should I imagine with that?

Ferry Schoenmakers:

Well, it’s a tractor that was designed from a blank sheet of paper. It’s completely newly built. As you can see: there’s no cabin, no seat, no steering wheel. It’s fully autonomous. That means the farmer makes a plan for what he wants to do that day, uploads it to the machine, presses start, and the machine carries out the entire plan. It works the land without the farmer needing to help. So the farmer has his hands free to do something else.

Interviewer:

A bit like a robotic lawn mower?

Ferry Schoenmakers:

Yes, actually. The difference is that a robotic mower aimlessly bumps around until it has done the whole field, whereas this machine really has a plan and drives in very neat lines across the field. But apart from that, you can compare the two.

Interviewer:

And what can it do?

Ferry Schoenmakers:

Ploughing, sowing, mowing, raking, digging – you name it. It can do all the soil work a farmer can do now. This machine is equipped at both the front and rear with a standard three-point hitch. That is exactly the same mechanical interface as a conventional tractor. So all the implements the farmer already has in the shed can be attached to this robot tractor and used for the same operations.

This is the hitch – it holds the implement. A standard hitch, just like on a normal tractor. Here above is the so-called top link. You connect that to the top of the implement. It can extend and retract, which lets you tilt the implement and set the correct working height.

Interviewer:

And that’s how you can control the implement? Is it already in use?

Ferry Schoenmakers:

Right now it’s mainly in use by AgXeed itself for a lot of testing. At the moment they have three machines operational, working on fields and giving demos across the Netherlands, Belgium and Germany. Next year they’ll go to their first customers. The idea is that the first ten early adopters will start working with it and become the owners of the first tractors.

Interviewer:

What does it cost?

Ferry Schoenmakers:

If I had to give a cautious price indication: this machine, with this engine and these rubber tracks, is around €250,000. If you compare that to a modern tractor – let’s say a Fendt with similar power and a GPS guidance system – you’re also looking at around two hundred thousand. So it’s a bit more expensive than a regular tractor.

If you look at this tractor, you’ll see a number of GPS antennas on top. Tractors with GPS guidance also have that. This one has two, so it not only knows where it is, but also which direction it’s facing – so it can steer very precisely and keep a straight line.

You also see a lidar system mounted on top. That is used to observe the surroundings and to stop for people or animals that accidentally stand in the way. Around the tractor there is also an ultrasonic system, as a last safety net. If something gets too close, the machine will brake.

Apart from that, in terms of sound, interface and control, it’s very similar to a normal tractor.

Interviewer:

And you are from Nobleo Technology?

Ferry Schoenmakers:

Correct, we are Nobleo Technology from Eindhoven. We focus on autonomous intelligent systems: autonomous machines and intelligent applications with smart sensors, vision systems and various mechanical systems. From our autonomy division we joined this project to develop the software for AgXeed’s machine – so that this tractor truly becomes a robot tractor.

Learn more

Read more about our work on agricultural autonomy on this page ‘autonomous technology for agriculture‘. Or for more indebt information feel free to contact us via the form below.