Focusing on performance, cost-efficiency and time to market, we deliver advanced mechatronic expertise that turn complex ideas into reliable, high performance systems ready for production.

Full-spectrum advanced mechatronics development across industries

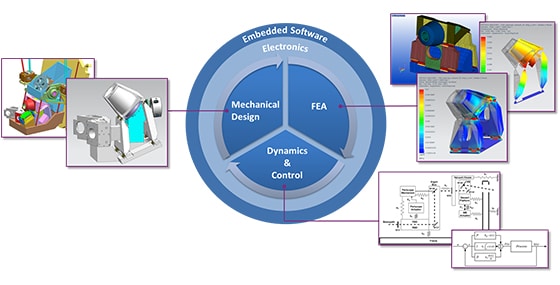

We are specialists in advanced mechatronics system design and development, serving a wide range of industries with performance-driven solutions. Our strength lies in the integration of mechanical, control, electronic and software disciplines into systems that deliver high performance (e.g. high precision, high throughputs), reliability and functionality.

With a consistent focus on performance, cost-efficiency and time to market, we support our customers in accelerating product development without compromising quality. Our design approach covers the entire product lifecycle. From initial concept and system architecture to prototyping, testing and production support. We apply proven engineering tools and validated development methodologies to ensure each system meets industry standards and customer-specific requirements.

Beyond engineering, we assist in setting up tailored supply chains, supervising New Product Introductions (NPI) and supporting manufacturing processes, all with full transparency and independence. This end-to-end approach ensures seamless transfer from development to production.

Whether the application involves submicron motion, dynamics, motion control or high-throughput handling, our multidisciplinary team is committed to turning complex ideas into robust, production-ready solutions—tailored for your market.

Our core advanced mechatronics expertise

Complex Mechatronics

Integrating mechanical, control, electronic and software disciplines for optimized system design.

Precision Engineering

Mechanical design know-how delivers sub-micron level accuracy.

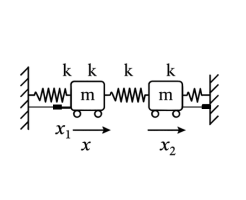

System Dynamics

Modeling, simulation, and experimental verification of dynamic behavior.

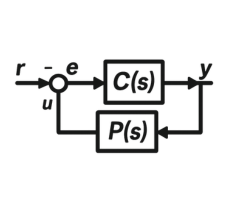

Servo Controller Designs

Applying control theory to achieve performance and stability.

Thermal Engineering

Applying our know-how to analyse, measure and design for handling heat loads and flow, allowing for optimal system performance.

Metrology

Using our competences on Mechanics, Dynamics and Sensing to design metrology systems which allow for sub-micron accurate measurements.

Assets that power our advanced mechatronics expertise

Nobleo Design Core

Within Nobleo the multidisciplinary design typical for mechatronics, is supported by our in house developed software tool chain in combination with our hands-on attitude. Enabling our engineers of different competence backgrounds to collaborate easy and efficiently on design and analyses , backed-up with fast experimental validation. All together ensuring convergence on optimal design solutions.

Design House+

We are not only providing our customers a design with corresponding Technical Product Documentation (TPD). We support our customers from end-to-end.

Being more than only a design house, we fulfil this support by setting up a tailored supply chain at jointly selected volume suppliers, handle NPI supervision and support on behalf of our customer. In the end wrapped up with turnkey industrialization and in-place Life Cycle Management (LCM).

All of the above in close cooperation with and full transparency towards our customer, safeguarding Nobleo’s full independence of potentially selected suppliers to serve our customers with the best tailored supply chain solution.

Industries we serve with mechatronic solutions

- Semiconductor

- Agri & Food

- Photonics

- Healthcare

Applications

- Submicron wafer handling systems

- Cleanroom-compatible high-tech modules

- Opto-mechanical modules for laser control

- High-throughput product handling lines

- Precision adhesive application systems

- Vibration-resistant optical frames

- Active mirror control modules

- Airbearing Performance Validation Systems

- Die handling systems (Tray, Tape Reel, Wafer)

Project examples (under NDA)

Mirror control module

Nobleo developed a mechatronic module consisting of multiple actively controlled mirrors, used for laser beam control. Challenge at the table was reaching robust beam control with sub micron accuracy, despite several sources of high frequency vibration disturbance. Project started at first requirements, remaining involved up to turn-key industrialized module at selected 3rd party.

Wafer transport system

We designed and developed a wafer handling system. Ensuring robust and accurate wafer handling at significant throughput rates. Besides common actuation and sensing technologies used to support the motion control, vision systems were used for qualification of results. Module was to used in ISO7 clean environment. NPI was managed and taken care of on-site at customer selected volume supplier located in the South-East Asia area.

Vegetable weighing and conveying system

Nobleo designed and developed a cost efficient prototype able to robustly handle a type of vegetable with a wide range of shapes, weights, and Center of Gravity at high throughput rates.

Die tray handling system

We designed and developed a mechatronic system to allow for an EFEM to place multiple trays at a buffer station, from where these trays were back and forth displaced to pick position. The latter in a manner where motion control, proper mechanical design and knowledge on use of both pneumatics and servo actuation plus sensing resulted in meeting the strict requirements on accuracy and precision. Supply Chain and NPI was managed and taken care of on-site at customer selected volume supplier located in the South-East Asia area.

Improved Shuttle system

Handled in a 3-month period, addressed the design & realization plus qualification of a Functional Model of an improved performance shuttle. Shuttle was able to do 90degrees cornering with 4-wheel-drive combined with high speeds and acceleration. Project success was based on our know-how of mechanics, motion control and software combined with our entrepreunrial spirit and agile supply chain management. Functional Model result properly addressed feasibility question.

Get in touch

"*" indicates required fields

Can I help you?

Ruud van der Aalst

Business unit director Mechatronic Systems

Trusted by industry leaders