Autonomous pallet truck

2 min read

2 min read - 30 Mar 2020

The Forklift Warehouse Management System

Challenges in AGV-based automation

Autonomous Guided Vehicles (AGVs) are increasingly used to automate logistical processes involving longer internal transport distances. However, developing an AGV alone isn’t sufficient to fully automate such a process.

In most warehouses, physical infrastructure must be installed to allow safe and reliable AGV navigation. In addition, dedicated software is often needed to integrate the AGV into a company’s specific logistics and IT landscape. These factors drive up development and operational costs, making AGV adoption economically viable only at large scale.

A standardized solution for pallet truck automation

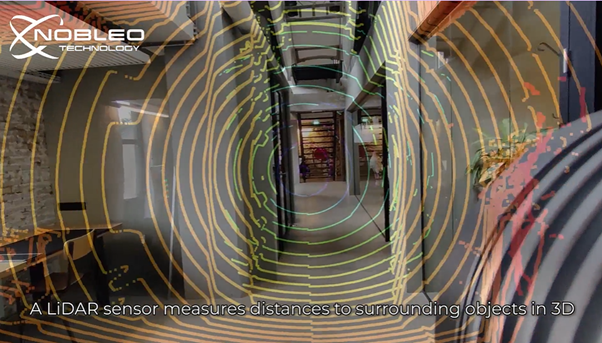

To overcome these barriers, Nobleo Project B.V. and Brightcape B.V. are jointly developing a standardized AGV solution for electric pallet trucks, called the Forklift Warehouse Management System.

This solution uses navigation based on relative displacement, allowing the AGV to move autonomously without the need for additional infrastructure. A generic Warehouse Management System (WMS) is also being developed, featuring standardized software interfaces (API couplings) and an intuitive user interface. This enables seamless integration with existing ERP systems and warehouse control processes, without the need for costly custom development.

Cost-effective AGV adoption for SMEs

By removing the need for custom infrastructure and software, this solution significantly lowers investment and development costs. As a result, AGV-based automation becomes accessible to small and medium-sized companies (MKB) as well and not just large players.

This project is partly subsidized and made possible by the Metropool Regio Eindhoven.

More information about Nobleo’s Autonomous Guided Vehicles (AGVs)

More information about Nobleo’s Autonomous Guided Vehicles (AGVs)

This project had been very successful, for an update and more information feel free to contact us by filling in the form below. For more information about our Autonomous Robot Solutions continue to visit this page.