Autonomous crawler testing for wind turbine blade inspection | part 2

The AIRTuB project (Automatic Inspection & Repair of Turbine Blades) is a collaborative R&D programme coordinated by @World Class Maintenance, focused on automating the inspection and repair of offshore turbine blades. The project integrates a drone capable of aerial inspection and landing, a crawler designed for surface navigation, and an advanced sensor suite for high-precision defect detection. The combined system aims to reduce maintenance downtime, improve safety, and extend the lifespan of offshore wind assets.

Autonomous inspection

As part of the AIRTuB project, we are developing the technology to make offshore wind turbine inspection fully autonomous. Following the successful flight tests in June 2025, a new milestone has been reached; the first driving test of the crawler platform on a turbine blade.

Nobleo’s crawler platform: design and purpose

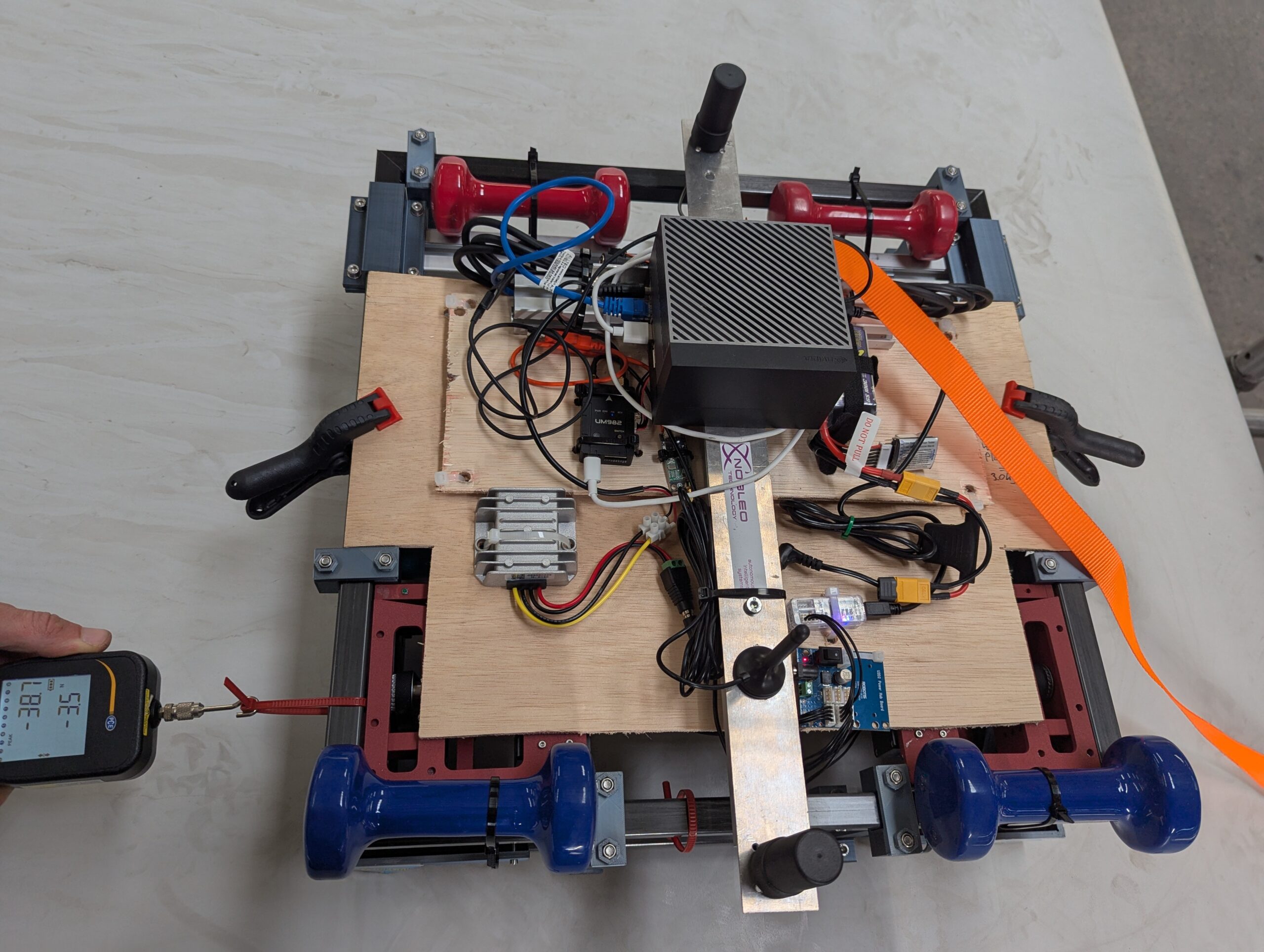

Nobleo is responsible for the design, mechanical architecture, and control software of the crawler system. The crawler must adhere to the curved, composite surface of turbine blades while maintaining traction and stability under various conditions such as wind, curvature, and blade texture.

During these early tests, Nobleo assessed:

- The crawler’s driving stability and traction on different sections of the blade;

- Odometry accuracy, measuring how precisely the system can estimate its position along the blade;

- The reachability of critical blade areas, to optimise inspection coverage for future autonomous operation.

Crawler test results – July 2025

On 29 July 2025, Nobleo performed the first on-blade driving test using a prototype crawler platform. The goal was to collect performance data and evaluate whether the crawler could safely and reliably move across the surface without slipping.

The results provided valuable insights into the crawler’s behaviour and the physical limits of its current design. These findings will guide the next design iteration, improving grip, motion control, and integration with the autonomous navigation software.

Next steps: integrating drone, crawler and sensor systems

The next development phase within AIRTuB will focus on system integration, merging drone, crawler, and sensor technologies to perform a complete autonomous blade scan. This includes synchronising flight navigation, landing control, and driving stability into one coordinated system.

📖 Missed the earlier story? Read part 1 – Flight test here: Nobleo’s autonomous drone inspection technology for offshore wind turbine blades

Contact us, for more information about our autonomous expertise and the solutions & services we offer.